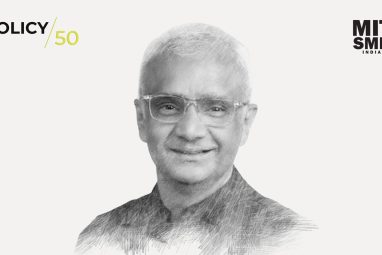

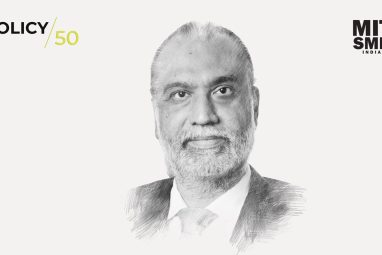

Pramod Kumar Mishra

Principal Secretary, PMO

Topics

News

- US-Iran Escalation: The Rising Risks to Middle East Projects and Investments

- Amazon Faces Dual Disruptions: Drone Strikes Hit AWS Sites as Retail Platform Stumbles

- Enterprise AI Scales Fast, but Structural Change Lags, Study Finds

- Inside OpenAI’s Pentagon Deal and the Three Red Lines on Military AI

- OpenAI Partners with Amazon and Microsoft

- Nvidia, Global Telecom Groups Back AI-Driven 6G Push

Pramod Kumar Mishra is the 13th and current Principal Secretary to the Prime Minister of India. A retired IAS officer of the 1972 Gujarat cadre, he holds an M.A. in Economics from the Delhi School of Economics, an M.A. in Development Economics, and a Ph.D. in Economics/Development Studies from the University of Sussex.

During his tenure as Additional Principal Secretary to the PM (2014–19), he introduced innovation and transformative reforms in human resource management, particularly in senior-level appointments. He is also credited with advancing flagship national programs such as the National Agriculture Development Program and the National Food Security Mission.

In recognition of his leadership in disaster risk reduction, Mishra received the United Nations Sasakawa Award, one of the world’s most prestigious honors in disaster management.

To view the full Policy 50 list, click here.