AI Can Improve How Humans and Robots Work

The modern warehouse represents the frontier of human-robot collaboration.

News

- UAE Banks Phase Out OTPs Amid Fraud Surge

- Data Leak at Abu Dhabi Finance Week Exposes Details of 700+ Delegates

- Alibaba’s Latest Open-Weight Qwen3.5 Enters a Crowded Field

- MBZUAI Secures $1M from Google.org to Narrow AI’s Language Divide

- UAE Emerges as Global Powerhouse, 42% of Firms Named ‘AI Leaders’

- Riyadh Launches Automated Traffic Compensation Under Osool Program

James Yang/theispot.com

WAREHOUSE AUTOMATION IS BOOMING as companies ramp up their use of robotics to deliver the lightning-fast logistics services required to meet today’s market demands. Teams of humans and robots will grow only more commonplace in these settings. By 2028, 80% of warehouses and distribution centers will deploy some form of robotics and/or warehouse automation, according to market research firm Gartner.1 But while these collaborations have improved operational performance, they are a long way from realizing their full potential.

Amazon, a company on the leading edge of warehouse automation, has faced ongoing complaints and criticism from employees in its fulfillment centers, who struggle to keep pace with the relentless speed of their robotic counterparts.2 The long-term pressure of working alongside robots has resulted in significant physical strain as well as serious accidents and injuries. A failure to address safety concerns among order pickers and other employees working within robotized systems can greatly erode their trust and willingness to collaborate. In this case, robots themselves are often underutilized, ultimately hurting efficiency and overall productivity.

Moreover, given that automation and robotics involve substantial capital investment and operating expenses, optimizing both human and robot resources to improve ROI is an imperative for warehouse managers. Studies have shown that having a mix of humans and robots can lead to greater efficiency, flexibility, and cost-effectiveness compared with full automation alone.3 But companies must carefully consider the respective roles that humans and robots should play in warehouse facilities.

These issues point to a critical need for innovation in the way humans and robots work together. While robots outperform humans in speed and precision, without effective collaboration, these advantages can be lost to system inefficiencies, dissatisfied and disengaged workers, and workplace hazards. Likewise, humans are inherently more flexible, adaptable, and creative than machines; a thoughtful approach to collaboration can maximize these strengths in highly automated work environments.

Our research at the MIT Digital Supply Chain Lab shows that AI has an important role to play not only in automating tasks but in facilitating human-robot collaboration (HRC) in warehouse operations. For example, large language models (LLMs) can make communication richer by combining text, audio, images, and videos to inform or assist workers. And AI-powered systems can assess operations with an eye toward fine-tuning performance and optimizing collaboration.

Human and Robot Roles in the Warehouse

Warehouses and distribution centers still rely heavily on human labor in e-commerce, despite automation technologies’ increasing importance in meeting demands for faster fulfillment. A variety of robots have been developed for specialized functions within warehouses, but they often have limited agility and adaptability. Humans typically outperform robots, for instance, when a task involves items of varying shapes, weights, and sizes. The combination of knowledge, skills, and experience also enables humans to make informed decisions and adapt to changing environments.

The need for human capabilities varies depending on the problem and its complexity. In modern warehouses, many operations performed by humans, such as picking items from racks and sorting them into bins, are increasingly orchestrated by assistive equipment like pick-to-light and put-to-light systems, respectively. These operations demand less human capability, since workers simply follow system cues rather than applying their own cognition or experience. Operations that require a higher level of human capability might include packing complex orders or processing order returns, since these cases require humans to make decisions and solve problems based on seasoned judgment.

The degree of robot autonomy — that is, the ability of robots to perform tasks independently of human supervision or direction — varies widely. Some robots execute simple, preprogrammed functions while others can navigate changes in their environment and adapt their behavior in real time. Robots with lower autonomy, such as automated guided vehicles (AGVs), mainly run under centralized control, on predefined paths, for navigation and task execution, such as transporting racks of goods from storage areas to picking stations. Highly autonomous robots, such as autonomous mobile robots (AMRs), are equipped with sophisticated sensors that allow them to dynamically plan their routes.

Because the operational circumstances in warehouses can vary significantly due to market demand, resource availability, and customer priorities, it is crucial for every manager to understand how to activate and combine the available levers. We have developed a framework to support managers in balancing human capability with robot autonomy.

Human-Robot Collaboration in Warehouses

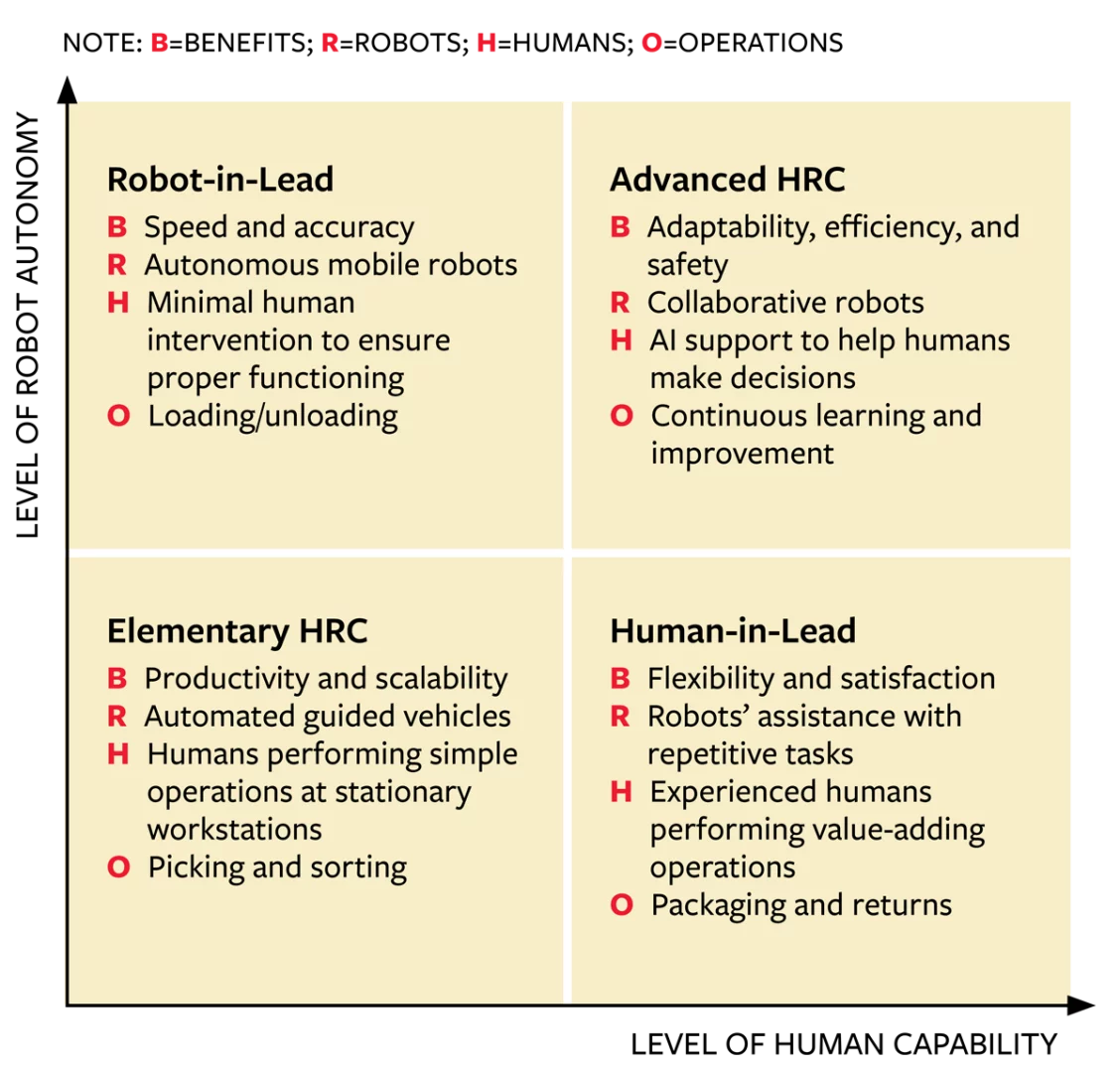

This framework describes the current contexts for managing warehouse operations where humans and automated systems work together — elementary HRC, robot-in-lead, and human-in-lead — and considers advanced HRC an aspirational target for some companies.

Mapping Out Human-Robot Collaboration

Our 2×2 framework categorizes HRC in warehouses based on the level of human capability and the level of robot autonomy present. (See “Human-Robot Collaboration in Warehouses.”) Let’s look at each of these in more detail:

Robot-in-lead. Robots can dominate operations when robot autonomy is high and the need for human capability is limited to oversight to ensure their proper functioning. For instance, logistics company DHL has applied dedicated robots to automate the unloading process in its warehouses, specifically for some health care logistics operations that typically require short lead times. These robots can autonomously detect, grasp, and place cargo with reliable performance and minimal human intervention, and they work faster than humans. Likewise, online retailers such as Zalando and Lloyd employ mobile robots in their shoe warehouses to automate the picking process. In each of these scenarios, robots apply their high level of autonomy to execute tasks with greater accuracy and consistency than humans can, reducing the likelihood of mistakes and boosting operational efficiency.

Human-in-lead. Humans take the lead in operations when robot autonomy is low and human capability is essential. This is common in warehouses where human judgment, dexterity, and cognitive skills are needed to handle tasks that robots cannot yet manage autonomously. However, robots are still employed to enhance efficiency by taking part in repetitive, routine tasks. For instance, in JD.com warehouses, humans select the most suitable box from a range of shapes and sizes to pack orders accurately, and they choose the appropriate filler materials for secure shipment. Afterward, robotic arms assist with sealing the boxes and affixing labels, streamlining the workflow. That task is straightforward and doesn’t require high-autonomy robots, but the robots relieve humans of mundane work. In contrast, most value-adding operations rely heavily on human capability, particularly in industries like luxury fashion, where small details can greatly impact brand reputation and foster long-term consumer trust and loyalty. Hermès, for example, uses premium packaging materials, such as tissue paper and ribbons, and involves human packers to ensure that the product presentation aligns with the expectations of the brand’s elite clientele.

Elementary HRC. Compared with robot-in-lead and human-in-lead situations, collaborative scenarios offer a dynamic middle ground that effectively blends the speed of robotics with human flexibility. Currently, HRC in warehouses is still in its early stages, with its most notable application being collaborative order picking. The success of Amazon Robotics has popularized robotic mobile fulfillment systems, which have become mainstream in modern e-commerce fulfillment. In these systems, AGVs are assigned to transport racks and humans are responsible for picking order items at stationary workstations. This arrangement significantly improves warehouse productivity, and it is scalable, since the number of robots and racks in use can be adjusted as needed. Recently, HRC has also gained traction in the sorting process. Deppon Logistics has implemented a robotic sorting system in its distribution centers to increase throughput capacity.4 In this setup, robots receive parcels or items from humans at workstations and transport them to designated drop-off locations for later shipment. This means that robots significantly reduce the physical endurance and travel distances required of humans, who, in turn, use their expertise to manage tasks effectively.

Advanced HRC. While elementary HRC prioritizes productivity and scalability, advanced HRC seeks to improve efficiency, adaptability, and safety by applying AI technologies. This is especially relevant for order picking in e-commerce, which is considered the most labor-intensive and time-consuming operation in the warehouse and accounts for more than half of warehousing costs. For example, using AI-reinforcement learning to optimize the order allocation process, and taking ergonomics into account, robots can be scheduled to match humans’ working states (in terms of speed or error corrections, for example), thus leading to reduced robot waiting times and improved utilization rates. Additionally, the coexistence of humans and robots in the workplace improves the system’s ability to adapt to manage unexpected disruptions, such as robot deadlocks and shutdowns. Based on the warehouse’s operational history, the network of robots could use AI to generate forward-looking scenarios to help advanced HRC deal with disruption. Advancements in AI should yield more collaborative robots (cobots) designed with safety measures like force limit and speed control, fostering a safer work environment.

The Role of AI in Advanced HRC

AI promises to be a vital tool in supporting improved human-robot interaction, particularly at its most advanced levels. It offers the highest value when applied to improving robots’ understanding of context, communication between robots and humans, customizing robot behavior to human needs, optimizing task performance, and supporting continuous improvement. Let’s look at each of these factors more closely.

Contextualization. AI augments robots’ contextual awareness in the warehouse and helps them better respond to their physical surroundings. For example, AMRs are usually deployed in designated low-traffic zones to minimize collision risks. However, with advances in computer vision and reinforcement learning, robots are emerging that can detect human movements with greater precision, such that they may be better able to share workspaces with humans. Moreover, AI-supported sensors can help robots recognize special handling needs, such as for fragile or perishable goods, and adjust their speed and grip pressure accordingly during transport. These advancements reduce the need for constant human oversight in routine operations, allowing people to concentrate on managing exceptions and making intricate, high-level decisions. During peak e-commerce events like Black Friday, online retailer Ocado uses AI demand predictive models that enable robots to prioritize tasks like restocking high-demand products and expediting the fulfillment of urgent orders.

Communication. AI enables smoother and more efficient communication between humans and robots. When advanced natural language processing techniques are employed, workers don’t need to use complex commands; they can send voice instructions to robots when their hands are occupied and receive easily understandable feedback. Additionally, LLMs allow for multimodal interactions, where humans can communicate with robots using images or videos. For example, at Maersk, workers are able to upload video information to communicate with robots, and an LLM interface can generate detailed instructions that robots can execute accurately. Furthermore, multiagent systems enable more sophisticated interactions and coordination among robots in the warehouse. This contributes to a synchronized flow of operations, where multiple robots coordinate tasks internally, thus reducing communication complexity between humans and the robot swarm.

Customization. AI allows robots to tailor their behavior to the unique preferences and workflows of individual humans. By accounting for factors such as fatigue, robots can adjust their pace to match the fluctuating states of the humans they are collaborating with. Task allocation informed by deep learning can improve collaborative efficiency in warehouse operations. In Amazon’s fulfillment centers, the movements of Kiva robots are optimized based on how fast humans can pick items, ensuring a smooth and continuous flow of operations. This level of customization ensures that human flexibility can be fully capitalized on while robots handle labor-intensive or repetitive tasks, improving system productivity and job satisfaction. AI also makes it easier for humans to transition between different roles as the system adapts to their evolving skills and provides necessary support. For example, skilled human pickers who are familiar with the warehouse layout and robot workflows can transition into roles as technicians who can monitor the robot fleet’s performance through dashboards or as managers who can train new employees to work most efficiently.

Task performance. AI enhances task performance in warehouses by continuously learning from operational data and improving task execution. For example, in the order-picking process, AI analyzes historical data to determine the fastest and most accurate routes for robots to take when retrieving items, reducing the travel time for each trip. Companies like DHL and Americold use AI to predict demand spikes and adjust operational capacity and robot operations in real time, minimizing downtime and ensuring faster order fulfillment. AI also enhances task accuracy; for example, robots equipped with AI vision systems can detect product defects or mislabeling errors before orders are shipped out. By providing timely feedback, AI allows robots to refine their performance significantly while alerting human supervisors to any abnormalities that require manual intervention, such as damaged goods or incorrect orders.

Continuous improvement. AI-driven continuous improvement enables robots and humans to enhance collaboration by constantly analyzing performance data and making adjustments. In warehouses, AI systems can monitor KPIs such as order accuracy, robot efficiency, and human-robot interaction times and then suggest interventions as needed, such as optimizing the layout to reduce travel times, reassigning tasks based on human strengths, or training operators through repetitive patterns. For example, at Alibaba’s smart warehouse, robots not only improve their own workflows over time but also provide feedback to humans on how to manage inventory more effectively. By fostering a culture of continuous learning, AI helps humans and robots alike to better fulfill their roles, allowing managers to achieve more efficient performance and adapt to changing demands.

Developing Advanced HRC Capabilities

Companies seeking to advance their HRC practices should focus on incremental progress, investing in systems where both robots and humans can gradually take on more sophisticated roles over time. For instance, advancing robot autonomy in repetitive tasks like picking and sorting while upskilling humans to manage logic-heavy responsibilities will help create a more reliable and efficient workforce.

Likewise, AI adoption should be approached as an ongoing journey rather than a onetime investment. Stakeholders should prioritize adaptive AI systems capable of achieving continuous optimization in warehouse operations. Additionally, developing AI-powered platforms that integrate data from multiple sources — including robots, human workers, and supply chain partners — can enhance operational efficiency and support tactical and strategic decision-making.

While robots are playing an increasing number of roles in warehouses, humans remain irreplaceable, especially in handling customer-focused tasks. Warehouse managers should exercise caution in pursuing fully automated operations, given that the costs of replacing human flexibility can be significant. At the same time, they should encourage warehouse workers to prioritize developing the new skills — such as becoming fluent in the use of LLMs — that are needed to effectively take advantage of robotic functions and collaborate with robots to maximize flexibility and performance.

The role of humans in HRC will shift from manual oversight to strategic management and exception handling. As HRC advances, stakeholders must retrain and upskill their human workforces. This human-centric approach allows people to collaborate with robots on advanced levels, ensuring that the integration of automation does not lead to a loss of human capability and instead enhances it. Strategic investment in training programs that help humans transition from low-level operational tasks to roles where they manage and improve AI-driven workflows will be crucial for long-term success.

The future of warehouse operations hinges on a delicate balance between human capability and robot autonomy, empowered by AI. Stakeholders who understand this dynamic and take actionable steps to integrate AI-driven HRC systems will gain significant competitive advantages in terms of efficiency, adaptability, and workforce satisfaction. While the journey to advanced HRC may be gradual, the key lies in recognizing the ongoing role of AI in improving every stage of collaboration. By focusing on continuous improvement, human-centric design, and strategic planning, warehouses can evolve into highly productive ecosystems where humans and robots work in harmony.

References

1. S. Tunstall, D. Klappich, R. Narang, et al., “Critical Capabilities for Warehouse Management Systems,” Gartner, Aug. 6, 2024, www.gartner.com.

2. A. Palmer, “Amazon’s Focus on Speed, Surveillance Drives Higher Warehouse Worker Injuries, Study Finds,” CNBC, Oct. 25, 2023, www.cnbc.com.

3. R. de Koster and D. Roy, “Warehouse and Logistics Automation Works Better With Human Partners,” Harvard Business Review, June 21, 2024, https://hbr.org.

4. B. Zou, R. De Koster, Y. Gong, et al., “Robotic Sorting Systems: Performance Estimation and Operating Policies Analysis,” Transportation Science 55, no. 6 (November-December 2021): 1430-1455, https://doi.org/10.1287/trsc.2021.1053.